Equip Your Warehouse for Peak Performance During Busy Seasons

As the calendar edges toward the year’s busiest months—warehouses and distribution centres everywhere brace for the annual surge in demand. While staffing and logistics grab much of the spotlight, one of the most overlooked strategies for conquering the seasonal rush is maximizing the efficiency and versatility of your existing material handling fleet.

In this comprehensive guide, we’ll explore how the right forklift attachments can transform your operation, boost productivity, and help you handle the pressures of the high season with agility and confidence.

Why Attachments Matter During Peak Season

Seasonal rushes bring with them unpredictability: more orders to fill, a wider variety of products, and increased pressure to deliver on time. Traditional forks are designed for standard pallets, but the reality of a busy warehouse often involves handling everything from bulky white goods and fragile electronics to oddly shaped holiday décor and perishables.

Forklift attachments are specialised add-ons fitted to the mast or forks of a forklift, allowing them to perform a diverse range of tasks. By equipping your fleet with the right attachments, you instantly increase the flexibility and safety of your operation—without the need for a major capital investment in new machinery

Popular Forklift Attachments for the Seasonal Rush

Let’s explore some of the most impactful attachments for seasonal highs:

1. Sideshift

These allow the forks to move laterally, making it easier to reposition loads without having to move the entire forklift. During peak periods, when space is at a premium and time is short, sideshift reduce the number of manoeuvres needed, cutting down unloading and loading times significantly.

2. Fork Positioners

When handling loads of varying widths, manually adjusting forks can slow down operations. Fork positioners allow the operator to move the forks closer or further apart hydraulically from inside the cabin. This not only saves time but minimizes the risk of damage to goods and strain injuries to workers.

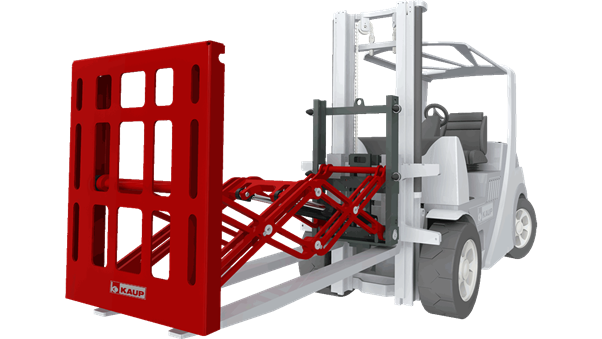

3. Carton Clamps

For warehouses dealing with large quantities of boxed or pallet-less goods—think electronics, white goods, or pre-packed holiday gifts—carton clamps are a game-changer. These attachments grip products securely from the sides, allowing for the safe lifting and transport of bulky yet delicate items.

4. Push/Pull Attachments

Handling slip-sheeted products (instead of traditional pallets) is increasingly common during busy seasons. Push/pull attachments grip the slip sheet and pull the load onto the forklift, then push it off at the destination. This not only saves on pallet costs but also streamlines the loading process for high-throughput environments.

4. Multi-Pallet Handlers

When speed is essential, being able to move two or more pallets simultaneously can be a game-changer. Multi-pallet handlers are invaluable in beverage, grocery, and manufacturing warehouses during the rush, doubling or tripling throughput with each pass.

5. Layer Pickers

Perfect for distribution centres and retailers, layer pickers allow operators to quickly select and move one layer of product at a time from a pallet. This dramatically improves picking efficiency during high-volume periods, especially for mixed-SKU shipments.

Investing for the Long Haul

While attachments are invaluable during seasonal surges, their benefits extend well beyond the rush. The right investment can deliver year-round flexibility, reduced labour costs, and improved safety. As supply chains face increasing volatility, adaptability becomes an organisation’s most powerful asset.